A Bespoke Dining Table: From Inquiry to Delight

Posted on May 19, 2025

The journey of a custom-made piece of furniture is often a testament to collaboration, precision, and the fulfilment of a specific need. This is precisely the story of a recent commission undertaken for a private customer residing in Suffolk.

The initial contact was made in September 2024, with an inquiry regarding a small, circular dining table. The client, while having a clear vision for the tabletop dimensions, expressed some uncertainty regarding the leg design. This presented an opportunity for a collaborative design process, allowing us to explore various options and determine the optimal solution.

The primary requirement was a tabletop of a specific size, coupled with an emphasis on providing ample, unhindered space for legs and feet. This consideration was paramount in ensuring both aesthetic appeal and practical functionality. We engaged in a series of discussions and consultations, meticulously refining the design to meet the client's precise needs.

The culmination of the design process for the table's structural support yielded a configuration emphasising both stability and aesthetic harmony. The final design incorporates a tripartite leg arrangement, a decision predicated on the principles of balanced load distribution. Each leg is reinforced by a series of support batons that converge at the central vertical axis. This support system was added to two strategic points: proximally, near the feet of the table, and just beneath the table's surface. This dual-point reinforcement provides optimal resistance against both vertical and lateral stresses, thereby enhancing the table's overall structural integrity.

By November 2024, a final design was agreed upon, encompassing the dimensions, materials, and leg design. The manufacturing process commenced promptly, and by the end of the month, the completed table was delivered to the client. Despite less-than-ideal weather conditions, the client was all too happy to provide photographic evidence of the table when it arrived at their property.

Click on the pictures to enlarge

The client was exceedingly pleased with the final product and their delight did not end with the initial delivery. In April 2025, a further order was placed for two additional tables of the same design. These were subsequently manufactured and delivered in May 2025, solidifying the client's satisfaction and reinforcing the value of bespoke craftsmanship. This project underscores the importance of attentive client communication, meticulous design, and the ability to translate a client's vision into a tangible, functional, and aesthetically pleasing piece of furniture.

Assembling the Table Frame: A Pictorial Walkthrough

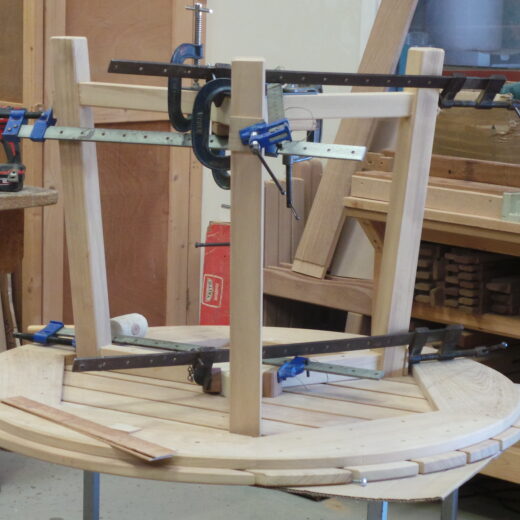

Here we detail the assembly of a tables, providing a comprehensive overview of the process. We had previously cut the lengths of timber to the correct size and had created the table surface. The stages of construction are presented here in a concise manner but hopefully give you an idea of the approach we took.

Construction and Clamping

The initial phase involved constructing the table leg frame and the table surface independently. This approach allowed for meticulous attention to detail in each component. Throughout the frame's construction, its positioning relative to the table surface was consistently monitored. This ensured optimal alignment and structural integrity when the two elements were eventually joined. This careful approach guaranteed seamless integration and maximum stability.

Click on the pictures to enlarge

Joining the Structures

Once the construction of both the table leg frame and the table surface met the required standards, the two structures were joined. Following this, both the table and its frame underwent a sanding process. This step was crucial for refining the surface and removing any imperfections, blemishes, or irregularities. This meticulous attention to detail contributed to the overall aesthetic appeal and durability of the final product.

Click on the pictures to enlarge

Packing and Transporting

After the completion of the construction and finishing processes, the circular tables were prepared for delivery. They were carefully packed and placed on a pallet. The tables were then transported to Suffolk, where the customer awaited their arrival. This final step marked the culmination of the construction process, ensuring the table reached its destination safely and efficiently.

Click on the pictures to enlarge

Final Notes

Completing a project like this marks the culmination of the collaborative effort, the realisation of a shared vision. The custom-made piece, now an integral part of the client's space, stands as a testament to the value of bespoke craftsmanship and the enduring appeal of objects created with care, precision, and a deep understanding of the client's needs. It is a tangible representation of the journey, a story told through the very form and function of the furniture itself.